Maximize the Profitability of your Recycling Program with a New Equipment Strategy

Lowering costs while increasing profits is the fundamental reason why most companies integrate recycling equipment into their Waste program. However, the decision to integrate one type of recycling equipment versus another can have far-reaching implications on the profitability and efficiency of your Waste Program.

Recycling Equipment decisions impact your entire Waste Program

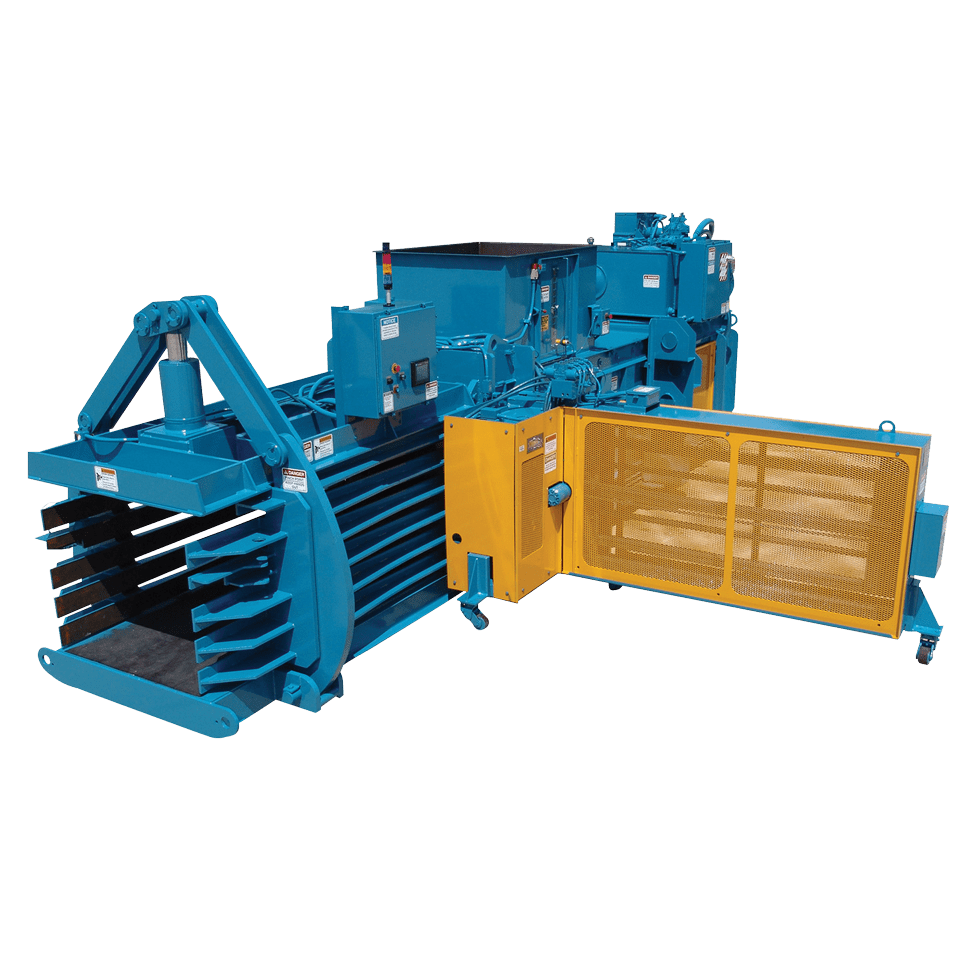

The most important piece of equipment in a recycling program is a recycling baler. Balers allow your company to compact material such as cardboard, shrink wrap, paper, packaging material clippings and light aluminum scrap. Material Management is here to help you make sense of the initial investment in baling equipment, and show you how it can lead to a more profitable recycling program:

Achieve the Maximum Rebate for every Haul — Hauling your recyclables is a fixed cost. Bailing your material makes sure you are maximizing all the available volume and achieving the maximum weight allowed for each haul you order. This type of optimization ensures you are earning the maximum possible rebate with each shipment of recyclable material.

Eliminate Excessive Hauling — Reducing the footprint of loose material is another issue that baling resolves. Baling material can reduce the space requirement of your recycling program by as much as 90% when compared to gaylord boxes and skips. This reduction in space occupied by recyclables greatly reduces the urgency and frequency of hauls that might have been a costly necessity to recover important space in your facility.

Improve Recyclable Material Marketability — Many mills and material processors simply do not accept loose material for logistical and processing reasons. Depending on your location, this limitation can significantly reduce your options to sell your recyclable material and in some cases makes it impossible.

Reduce Staffing/Labor Costs — Preparation of loose recycling waste can be labor-intensive. For instance, your staff will have to handle cardboard (OCC) waste several times before it is picked up: tearing/cutting to reduce the space required in the skip or bin and preparing and moving empty containers that fill up quickly.

The Benefits of the Right Recycling Equipment go far Beyond Profitability

Health and Safety — Accumulating loose material in skips and bins can create a fire risk for many facilities. Excessive processing of waste material is repetitive and can add health concerns for your employees. Recycling bins and skips also occupy a large amount of space in your facility and can therefore restrict safe movement of your staff.

Cleanliness — Material in skips and bins can unintentionally create perfect homes for rodents and other places to hide in your facility.

Reduced Carbon Footprint — A welcomed side-effect of fewer hauls is the reduction of your carbon emissions accumulated to transport your waste to a recycling facility or mill.

Choosing the Right Baler for your Waste Program

Determining the right baler for your waste program can be daunting. Baling equipment are as unique as the needs of each individual program. Balers roughly fit in to the following categories:

- Vertical Balers — These balers are relatively inexpensive, and suitable for franchise stores, small manufacturing companies, parks, airports, hotels, supermarkets, healthcare institutions, and fast-food chains. Vertical balers require some manual labor for unloading and unloading waste material.

- Single-Ram Horizontal Balers — Suitable for low to medium-sized industrial installations, horizontal balers require more space than vertical balers, however, they require less manual labor, produce denser bales, and support more types of material.

- Dual-Ram Horizontal Balers — These balers have the same advantages of single-ram, horizontal balers with the added benefit of producing denser bales.

For over 18 years, Material Management have been helping our customers choose the right baler for their Waste Program. From mini balers costing just over $1000, to complex installations requiring over $1 million dollars of engineering and equipment investment, we have the experience to help you make the right equipment choices. Let Material Management help your company develop a new equipment strategy today.